Expert Insights

In today’s global manufacturing landscape, companies face numerous challenges, such as rising manufacturing labor costs, supply chain disruptions, and intense international competition. Against this backdrop, advanced manufacturing solutions—automation and artificial intelligence (AI), have emerged as essential tools for achieving cost savings in manufacturing and enhancing operational efficiency.

KEY TAKEAWAYS:

This article focuses on how automation and AI drive cost savings in manufacturing, exploring in depth their mechanisms of action, the benefits they bring, and relevant industry trends.

A. Their core logic and pathways to cost reduction in the manufacturing industry.

B. Automation and AI advanced manufacturing solution’s international trends and investment value.

C. The key role of automation and AI technologies in cost savings in manufacturing.

The Core Logic to Cost Savings in Manufacturing

Manufacturing costs mainly cover several aspects, including raw materials, labor, energy, and equipment maintenance. Automation and AI technologies can achieve cost savings in manufacturing at multiple stages.

Firstly, the use of advanced automated equipment can precisely control the consumption of raw materials, improve their utilization rate, and thereby reduce the cost of raw materials.

Secondly, these technologies drastically reduce the reliance on manual labor for repetitive or hazardous tasks, directly impacting manufacturing labor costs. By automating these processes, companies can reallocate human resources to more complex, value-added activities, thereby maximizing human potential.

Thirdly, AI-driven analytics provide unparalleled insights into production processes. This allows for predictive maintenance, minimizing unexpected downtime and the associated costs of repairs and lost production.

In terms of energy costs, automation and AI technologies can optimize production processes and equipment operations to achieve efficient energy use. For example, intelligent energy management systems can adjust the operating status of equipment in real time based on production demands, avoiding idling and energy waste, thereby reducing energy consumption and related costs.

Finally, implementing robust cost accounting in manufacturing industry practices alongside these manufacturing cost savings ideas allows for precise tracking and measurement of financial benefits.

Trends and Investment Value of Automation and AI

Globally, manufacturers are accelerating their investments in automation and AI to maintain competitiveness. For instance, Ford’s $1 billion investment in AI-driven automation led to a 20% increase in production efficiency and a 15% reduction in operational costs within three years. Similarly, Airbus’s aggressive adoption of AI-powered quality control reduced defects by 30%, outperforming competitors who delayed AI integration.

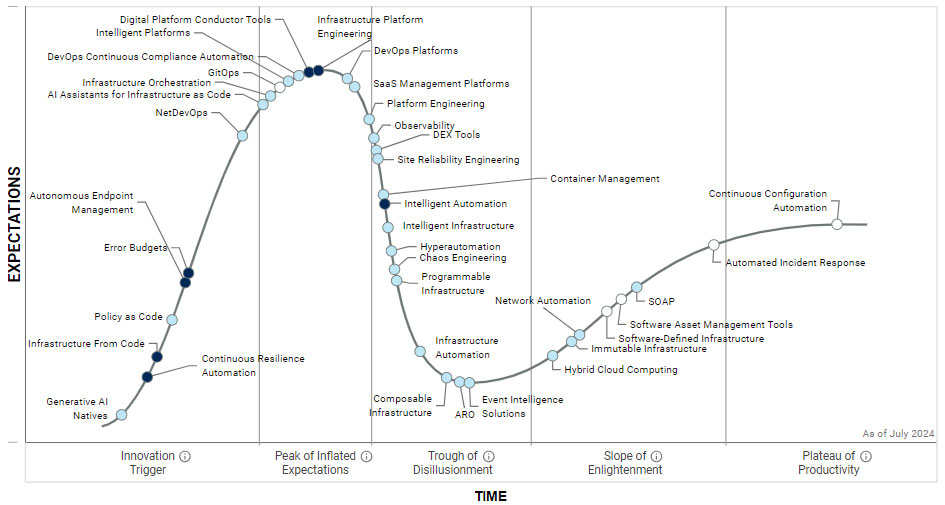

Industry reports reveal that AI and automation can reduce operational costs by 20-30% and improve efficiency by over 40%. Gartner forecasts that Hyperautomation will continue to be the primary technological direction for 90% of large enterprises. These trends underscore the growing recognition of automation as a critical driver of cost savings in manufacturing.

Source: Gartner

Benefits Brought by Automation and AI Technologies

In summary, the integration of automation and AI technologies offers a transformative pathway to achieving significant cost savings in manufacturing.

1. Reduce manufacturing labor cost

2. Minimize operational waste

3. Optimizing energy consumption

4. Improving overall production efficiency.

By enabling predictive maintenance and data-driven decision-making, automation and AI not only streamline existing processes but also foster innovation and adaptability. Ultimately, their positive impact on cost savings in manufacturing positions businesses for greater profitability, resilience, and a competitive edge in the evolving global market.

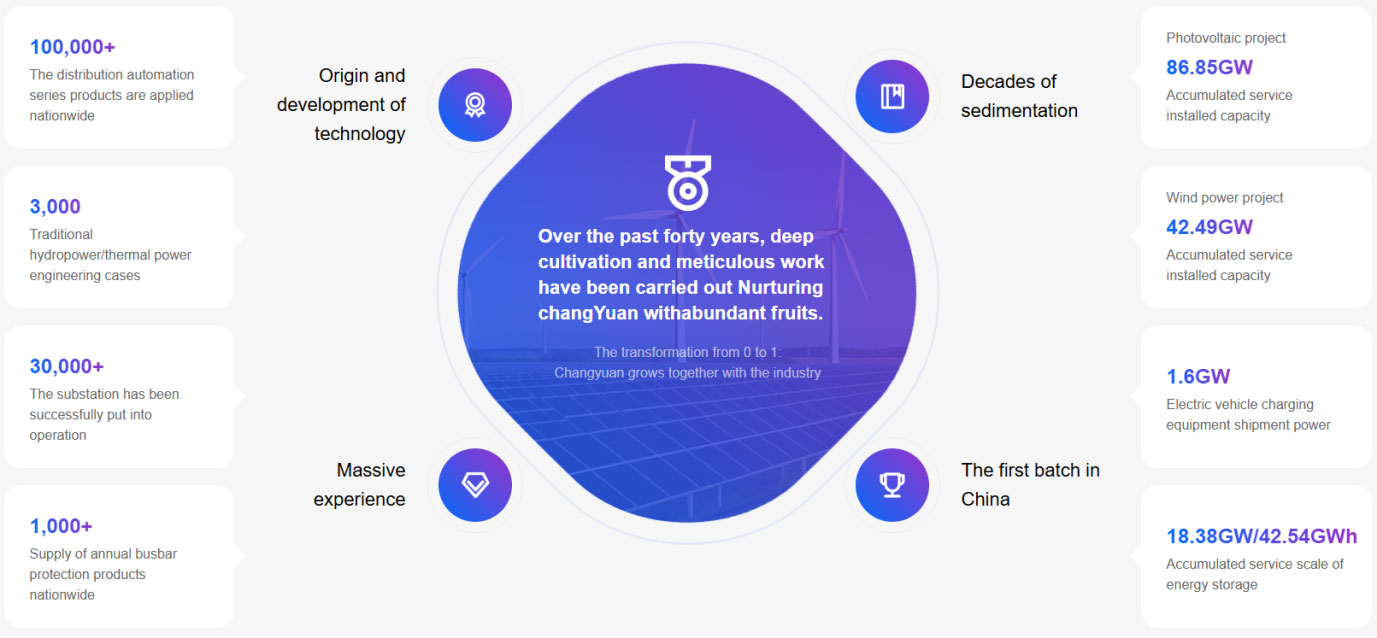

Contact CYG PTABG for the Latest Automation and AI Solutions

Changyuan Technology Group (CYG) offers customized intelligent equipment and solutions to help enterprises achieve automation and intelligence. In the current manufacturing landscape, where many challenges are faced, we encourage companies to actively adopt automation and AI technologies to improve production efficiency and realize cost savings in manufacturing.

CYG Precision Test & Automation Business Group (CYG PTABG) is one of CYG's five core business groups. CYG PTABG is dedicated to the research, development, production, and sales of intelligent equipment across various industries, providing comprehensive testing and automation solutions to global clients. Our business scope covers multiple downstream application scenarios, such as consumer electronics, industrial electronics, automotive electronics, new energy, semiconductors, medical, and food industries.

Free contact us to further explore the potential for cost savings in manufacturing in your enterprise.